The 5A05 marine grade aluminum plate is an Al-Mg rust-proof aluminum alloy, which cannot be heat-treated and the cold deformation of the alloy can improve the strength. The plasticity in the annealed state is high, and the plasticity in the semi-cold hardening state is acceptable. The alloy has good corrosion resistance and good weldability, and is suitable for spot welding, atomic hydrogen welding, gas welding, and argon arc welding. Its machinability, semi-cold hardening state is still good.

Common specifications: 0.15-600mm

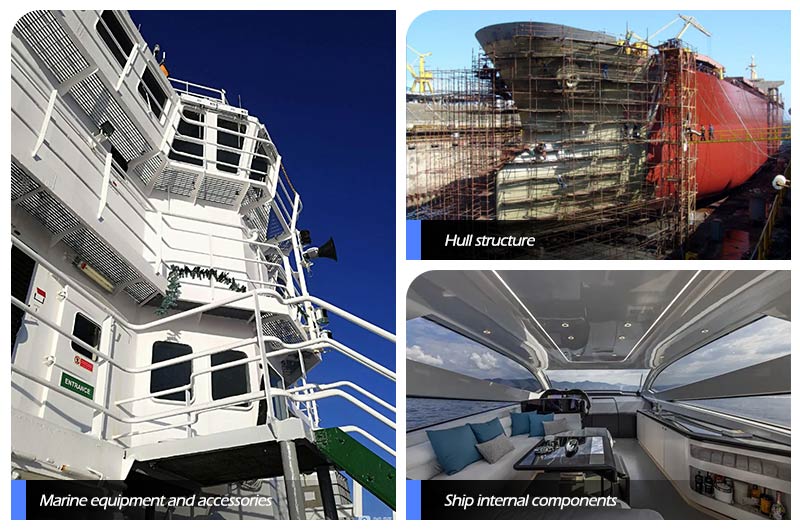

Application areas: armor plates, high-strength structural parts, ship sheet metal parts, fuel tanks, etc.

Processing technology: hot rolling

| Alloy | Temper | Thickness (mm) | Width (mm) | Length (mm) | Application |

| 5A05 | O,H12,H14, H16,H18,H19, H22,H24,H26, H28,H32,H34 H36,H38,H111, H112,H114,H 116,H321 | 0.15-600 | 20-2600 | 500-16000 | Ship sheet metal parts, fuel tanks, flanges, etc. |

Performance advantage

1. The cold deformation strength of 5A05 marine grade aluminum plate is high, the plasticity in the annealed state is high, and the strength is low, and the corrosion resistance and weldability are good;

2, semi-cold hardening state, good machinability;

3. The surface of the aluminum plate has no peeling, air bubbles, rough surface and local mechanical damage, and the surface of the aluminum plate has no defects;

4. We have 6 semi-continuous casting production lines, 10 continuous casting and rolling production lines, and 44 other large processing equipments, with an annual output of 450,000 tons, which provides a solid foundation for the large-scale production of 5A05 marine grade aluminum plate.

| Thickness | Thickness tolerances for the following widths | ||

| ≤1500 | >1500-2000 | >2000 | |

| 3.00-4.00 | +0.10-0.10 | +0.17-0.15 | +0.23-0.15 |

| >4.00-8.00 | +0.20-0.20 | +0.23-0.20 | +0.28-0.25 |

| >8.00-12.00 | +0.38-0.25 | +0.51-0.25 | +0.58-0.25 |

| >12.00-20.00 | +0.50-0.35 | +0.60-0.40 | +0.65-0.50 |

| >20.00-50.00 | +0.65-0.45 | +0.75-0.50 | +0.90-0.65 |

| Different vessel sizes, types and uses may require different aluminum sheet sizes and shapes. In order to ensure proper size and quality, it is recommended to contact haomei aluminum premium marine aluminum plate suppliers for detailed consultation and negotiation to determine the most suitable 5a05 marine aluminum plate size for a specific marine project. | |||

1. The cold deformation strength of 5A05 marine grade aluminum plate

is high, the plasticity in the annealed state is high, and the strength

is low, and the corrosion resistance and weldability are good;

2, semi-cold hardening state, good machinability;

3. The surface of the aluminum plate has no peeling, air bubbles, rough

surface and local mechanical damage, and the surface of the aluminum

plate has no defects;

4. We have 6 semi-continuous casting production lines, 10 continuous

casting and rolling production lines, and 44 other large processing

equipments, with an annual output of 450,000 tons, which provides a

solid foundation for the large-scale production of 5A05 marine grade

aluminum plate.

Hull structure: 5a05 marine aluminum plate can be used for structural components such as hull shell, ship bulkhead, ship bottom and deck. It has good strength and corrosion resistance, and can withstand the pressure of seawater and long-term use without damage.

Ship internal components: various components inside the ship, such as partitions, ceilings, floors and cabin doors, can also be made of 5a05 marine aluminum plates. Its lightweight properties help to reduce the weight of the ship itself and improve the ship's load capacity and fuel economy.

| Alloy | Temper | Thickness mm |

| 5A05 | O | 3.00-6.00 |

| H112 | 6.00-50.00 |