Marine grade aluminum pipe refers to aluminum pipe designed and manufactured specifically for use in marine environments. Made of aluminum alloy, these tubes are engineered to withstand the harsh conditions typically encountered in marine applications, such as exposure to salt water, moisture and corrosive elements.

Aluminum tubes used in marine applications are commonly used in a variety of ship structures, including frames, railings, mast supports and other components, where lightweight, corrosion-resistant materials are critical for long-term performance and safety.

These pipes and tubes are often manufactured to meet specific industry standards and may have additional treatments or coatings to increase their resistance to corrosion and other environmental factors.

Marine Aluminum Tube Specifications Measurement Chart

| Diameter (D) mm | 22 | 35 | 45 | 50 | 60 | 70 | 80 | 108 | 120 | 130 |

| Thickness (T) mm | 3 | 5 | 4 | 3 | 6 | 5 | 5 | 8 | 5 | 10 |

Marine-grade aluminum tubes generally use alloys 6061, 6063, and 6082. These aluminum tubes each have unique advantages in marine and ocean environments.

Applications

Applications

Applications

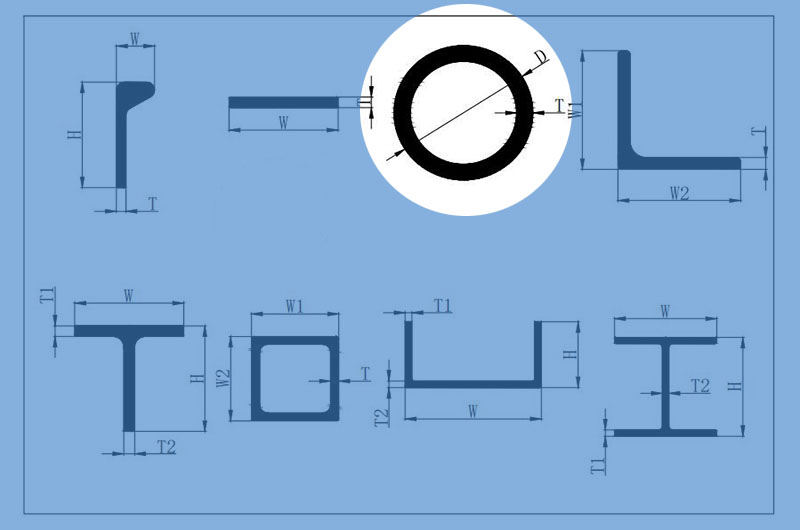

Marine-grade aluminum tubing comes in a variety of shapes and sizes, depending on its intended use and application.

| Element | 6061 Aluminum Alloy | 6063 Aluminum Alloy | 6082 Aluminum Alloy |

| Aluminum (Al) | Remainder | Remainder | Remainder |

| Silicon (Si) | 0.40-0.80% | 0.20-0.60% | 0.70-1.30% |

| Iron (Fe) | 0.70% Max | 0.35% Max | 0.50% Max |

| Copper (Cu) | 0.15-0.40% | 0.10% Max | 0.10-0.40% |

| Manganese (Mn) | 0.15-0.40% | 0.10% Max | 0.40-0.70% |

| Magnesium (Mg) | 0.80-1.20% | 0.45-0.90% | 0.60-1.20% |

| Chromium (Cr) | 0.04-0.35% | 0.10% Max | 0.25% Max |

| Zinc (Zn) | 0.25% Max | 0.10% Max | 0.10% Max |

| Titanium (Ti) | 0.15% Max | 0.10% Max | 0.10% Max |

| Lead (Pb) | 0.15% Max | 0.10% Max | 0.10% Max |

| Product Name | Specifications (mm) | Brand | Mold No. | Weight per meter (kg/m) | Fixed length(m) | Previous period inventory |

| Round Tube | Ф20*3 | 6082-T6 | YH-HZ-Ф20*3 | 0.436 | 6 | 333.5 |

| Round Tube | Ф22*3 | 6063-T6 | YH-HZ-Ф22*3 | 0.487 | 6 | 155 |

| Round Tube | Ф22*3 | 6082-T6 | YH-HZ-Ф22*3 | 0.487 | 6 | 190 |

| Round Tube | Ф25*3 | 6082-T6 | HZAL-17 | 0.564 | 6 | 192.5 |

| Round Tube | Ф25*3 | 6061-T6 | HZAL-17 | 0.564 | 6 | 155 |

| Round Tube | Ф27*2.87 | 6082-T6 | YH-HZ-Ф27*2.87 | 0.592 | 6 | 369.5 |

| Round Tube | Ф30*3 | 6082-T6 | YH-HZ-Ф30*3 | 0.692 | 6 | 421.5 |

| Round Tube | Ф30*4 | 6082-T6 | YH-HZ-Ф30*4 | 0.889 | 6 | 94 |

| Round Tube | Ф32*3 | 6063-T6 | Ф32*3 | 0.743 | 6 | 85 |

| Round Tube | Ф32*3 | 6082-T6 | Ф32*3 | 0.743 | 6 | 278 |

| Round Tube | Ф32*4 | 6082-T6 | YH-HZ-Ф32*4 | 0.957 | 6 | 341 |

| Round Tube | φ34*3 | 6082-T6 | YH-HZ-φ34*3 | 0.795 | 6 | 245 |

| Round Tube | Ф34*4 | 6082-T6 | Ф34*4 | 1.025 | 6 | 302 |

| Round Tube | Ф34*5 | 6082-T6 | YH-HZ-Ф34*5 | 1.239 | 6 | 334 |

| Round Tube | Ф34*8 | 6082-T6 | YH-HZ-Ф34*8 | 1.777 | 6 | 94 |

| Round Tube | Ф35*3 | 6082-T6 | YH-HZ-Ф35*3 | 0.82 | 6 | 225.5 |

| Round Tube | Ф35*5 | 6082-T6 | YH-HZ-Ф35*5 | 1.282 | 6 | 64 |

| Round Tube | Ф38*3 | 6082-T6 | Ф38*3 | 0.897 | 6 | 9 |

| Round Tube | Ф38*4 | 6082-T6 | YH-HZ-Ф38*4 | 1.162 | 6 | 269 |

| Round Tube | Ф40*4 | 6082-T6 | YH-HZ-Ф40*4 | 1.231 | 6 | 210.5 |

| Round Tube | Ф40*8 | 6082-T6 | YH-HZ-Ф40*8 | 2.188 | 6 | 200 |

| Round Tube | Ф42*3 | 6082-T6 | HZAL-Ф42*3 | 1 | 6 | 455 |

| Round Tube | Ф42*3.5 | 6082-T6 | YH-HZ-Ф42*3.5 | 1.151 | 6 | 251 |

| Round Tube | Ф42*3.5 | 6063-T6 | YH-HZ-Ф42*3.5 | 1.151 | 6 | 53 |

| Round Tube | Ф42*4 | 6082-T6 | YH-HZ-Ф42*4 | 1.299 | 6 | 131 |

| Round Tube | Ф45*4 | 6082-T6 | YH-HZ-Ф45*4 | 1.401 | 6 | 56 |

| Round Tube | Φ48*3 | 6082-T6 | YH-HZ-Φ48*3 | 1.154 | 6 | 123.5 |

| Round Tube | φ48*4 | 6082-T6 | YH-HZ-φ48*4 | 1.504 | 6 | 81 |

| Round Tube | Φ48*5 | 6082-T6 | YH-HZ-Φ48*5 | 1.837 | 6 | 151.5 |

| Round Tube | Ф50*3 | 6082-T6 | Ф50*3 | 1.205 | 6 | 155.5 |

| Round Tube | Ф50*4 | 6082-T6 | Ф50*4 | 1.572 | 6 | 119 |

| Round Tube | Ф50*4.5 | 6082-T6 | YH-HZ-Ф50*4.5 | 1.75 | 6 | 66.67 |

| Round Tube | Ф51*5 | 6082-T6 | YH-HZ-Ф51*5 | 1.965 | 6 | 88.667 |

| Round Tube | Ф60*3 | 6082-T6 | YH-HZ-Ф60*3 | 1.461 | 12.2 | 24 |

| Round Tube | Ф60*3 | 6082-T6 | YH-HZ-Ф60*3 | 1.461 | 6 | 76 |

| Round Tube | Ф60*4 | 6082-T6 | YH-HZ-Ф60*4 | 1.914 | 6 | 89 |

| Round Tube | Ф60*5 | 6082-T6 | Ф60*5 | 2.35 | 6 | 94.5 |

| Round Tube | Φ60*6 | 6082-T6 | Φ 60*6 | 2.769 | 6 | 62.5 |

| Round Tube | Φ60*8 | 6082-T6 | Φ 60*8 | 3.555 | 6 | 112 |

| Round Tube | Φ65*4 | 6082-T6 | YH-HZ-Ф65*4 | 2.085 | 6 | 186 |

| Round Tube | Ф70*6 | 6082-T6 | Ф70*6 | 3.281 | 6 | 18 |

| Round Tube | Ф75*4 | 6082-T6 | YH-HZ-Ф75*4 | 2.427 | 12.2 | 28 |

| Round Tube | Ф75*4 | 6082-T6 | YH-HZ-Ф75*4 | 2.427 | 6 | 80 |

| Round Tube | Φ75*7 | 6082-T6 | YH-HZ-Φ75*7 | 4.067 | 6 | 71 |

| Round Tube | Ф76*5 | 6082-T6 | YH-HZ-Φ76*5 | 3.034 | 6 | 116 |

| Round Tube | Ф76*6 | 6082-T6 | HZAL-6 | 3.589 | 6 | 87.5 |

| Round Tube | Ф80*4 | 6082-T6 | YH-HZ-Φ80*4 | 2.598 | 6 | 21 |

| Round Tube | Ф80*5 | 6082-T6 | YH-GC-001 | 3.181 | 6 | 3.4 |

| Round Tube | Φ80*8 | 6082-T6 | Φ80*8 | 4.922 | 6 | 57 |

| Round Tube | Ф80*10 | 6082-T6 | Ф80*10 | 5.982 | 6 | 33 |

| Round Tube | Ф85*5 | 6082-T6 | YH-HZ-Ф85*5 | 3.418 | 6 | 115 |

| Round Tube | Ф89*4.05 | 6082-T6 | YH-HZ-Ф89*4.05 | 2.94 | 6 | 74.5 |

| Round Tube | Ф89*5 | 6082-T6 | Ф89*5 | 3.589 | 6 | 101 |

| Round Tube | Ф89*8 | 6082-T6 | YH-HZ-Ф89*8 | 5.537 | 6 | 76 |

| Round Tube | Ф90*6 | 6082-T6 | Ф90*6 | 4.307 | 6 | 97 |

| Round Tube | Ф90*8 | 6082-T6 | Ф90*8 | 5.606 | 6 | 49.5 |

| Round Tube | Ф90*10 | 6082-T6 | YH-HZ-Ф90*10 | 6.836 | 6 | 15 |

| Round Tube | Φ100*4 | 6082-T6 | YH-HZ-Φ100*4 | 3.281 | 6 | 0 |

| Round Tube | Φ100*5 | 6082-T6 | Φ100*5 | 4.059 | 6 | 20.5 |

| Round Tube | Φ100*10 | 6082-T6 | Φ 100*10 | 7.691 | 6 | 25 |

| Round Tube | Φ101.6*6.35 | 6082-T6 | YH-HZ-Φ101.6*6.35 | 5.168 | 6 | 0 |

| Round Tube | Ф102*6 | 6082-T6 | HZAL-7 | 4.922 | 6 | 37.5 |

| Round Tube | Ф108*4 | 6082-T6 | YH-HZ-Ф108*4 | 3.555 | 6 | 86 |

| Round Tube | Ф108*8 | 6082-T6 | YH-HZФ108*8 | 6.836 | 6 | 48 |

| Round Tube | Ф108*8 | 6061-T6 | YH-HZФ108*8 | 6.836 | 6 | 28 |

| Round Tube | Ф110.3*5 | 6082-T6 | YH-HZ-Ф110.3*5 | 4.499 | 6 | 76.5 |

| Round Tube | Ф110*10 | 6063-T6 | 8.545 | 3 | 4 | |

| Round Tube | Ф114.3*6 | 6082-T6 | Ф114.3*6 | 5.553 | 6 | 32.5 |

| Round Tube | Ф114.3*8.6 | 6082-T6 | YH-HZ-Ф114.3*8.6 | 7.768 | 6 | 57 |

| Round Tube | Ф115*9 | 6082-T6 | Ф115*9 | 8.152 | 6 | 7 |

| Round Tube | Ф120*5 | 6082-T6 | Ф120*5 | 4.913 | 6 | 65 |

| Round Tube | Ф120*6 | 6082-T6 | YH-HZ-Ф120*6 | 5.845 | 6 | 17.38 |

| Round Tube | Ф120*10 | 6082-T6 | Ф120*10 | 9.399 | 6 | 44 |

| Round Tube | Ф125*3 | 6082-T6 | Ф125*3 | 3.128 | 6 | 151.5 |

| Round Tube | Ф127*19 | 6082-T6 | YH-HZ-Ф127*19 | 17.535 | 6 | 4 |

| Round Tube | Ф130*5 | 6082-T6 | YH-HZ-Ф130*5 | 5.341 | 6 | 34 |

| Round Tube | Ф130*10 | 6082-T6 | Ф130*10 | 10.254 | 6 | 6 |

| Round Tube | Ф140*6 | 6082-T6 | YH-HZ-Ф140*6 | 6.87 | 6 | 12.5 |

| Round Tube | Ф140*10 | 6082-T6 | Ф140*10 | 11.109 | 6 | 18 |

| Round Tube | Ф150*5 | 6082-T6 | YH-HZ-Ф150*5 | 6.195 | 6 | 8.5 |

| Round Tube | Ф150*10 | 6082-T6 | Ф150*10 | 11.88 | 6 | 3 |

| Round Tube | Ф150*12 | 6082-T6 | YH-HZ-Ф150*12 | 14.151 | 6 | 13.467 |

| Round Tube | Φ160*10 | 6082-T6 | Φ160*10-A | 12.818 | 6 | 27 |

| Round Tube | Ф170*7 | 6082-T6 | Ф170*7 | 9.75 | 6 | 38 |

| Round Tube | Ф170*10 | 6082-T6 | Ф170*10 | 13.672 | 6 | 18 |

| Round Tube | Ф180*15 | 6082-T6 | Ф180*15 | 21.14 | 6 | 13 |

| Round Tube | Ф190*11 | 6082-T6 | Ф190*11 | 16.825 | 6 | 20.5 |

| Round Tube | Ф190*12 | 6082-T6 | Ф190*12.5 | 18.96 | 6 | 19 |

| Round Tube | Ф190*20 | 6082-T6 | Ф190*20 | 29.053 | 6 | 10 |

| Round Tube | Ф210*5 | 6082-T6 | Ф210*5 | 10.036 | 6 | 39 |

| Round Tube | Ф216*12.7 | 6082-T6 | YH-HZ-Ф216*12.7 | 22.063 | 6 | 16 |

| Round Tube | Ф280*10 | 6082-T6 | Ф280*10 | 23.072 | 6 | 5.5 |

Aluminum tubes used in marine applications are commonly used in a variety of ship structures, including frames, railings, mast supports and other components, where lightweight, corrosion-resistant materials are critical for long-term performance and safety.