Aluminium plate Supplier

Aluminium plate Supplier

Aluminum circle is also known as aluminum disc, which is a perfect material for making aluminum round metal. It is usual with thickness from 0.3mm-10mm, and a diameter from 100mm-800mm. It is widely used in electronics, daily chemicals, medicine, culture and education, auto parts, and other industries. Mainly, 1xxx and 3xxx aluminum circles are used for making kitchen utensils, cookware such as non-stick pans, saucepans, pizza pans, pressure cookers, and other hardware such as lampshades, water heater casings, etc. Our aluminum circles are made in accordance with international standards ASTM B209, ASME SB 221, EN573, and EN485.

Aluminium Circle is a metal product that is subjected to flying shear after being rolled and bent by a casting and rolling mill. It is widely used in electronics, packaging, construction, machinery, etc. According to the different metal elements contained in the Aluminium Circle, the Aluminium Circle can be roughly divided into 9 categories, that is, it can be divided into 9 series.

Aluminium Circle main use in household kitchen utensils,electrical equipment, heat preservation,machine manufacuring ,aeronautics& astronautics,war industry,mold,printing and so on .

The quality policy of Haomei is to establish, implement, and maintain an effective assurance system based on ISO 9001 with the full participation of all employees in the process of continuous quality improvement and quality assurance practices resulting in total customer satisfaction. By encouraging open communication, we are dedicated to achieve true and sincere partnership with both internal and external customers resulting in total customer satisfaction.

The purpose of our quality system is to continuously improve the quality of our products, our services, and productivity in order to achieve internal and external customer satisfaction.

Alloy | Temper | Specification | |

Thickness(mm) | Diameter(mm) | ||

1050,1060 1070,1100,3003 | O,H12,H14 | 0.40—6.0 | 20--1200 |

TEMPER | THICKNESS(mm) | TENSILE STRENGTH | ELONGATION% | Standard | ||||||||||||||||

HO | 0.36-6 | 60-100 | ≥ 20 | GB/T91-2002 | ||||||||||||||||

H12 | 0.5-6 | 70-120 | ≥ 4 | |||||||||||||||||

H14 | 0.5-6 | 85-120 | ≥ 2 | |||||||||||||||||

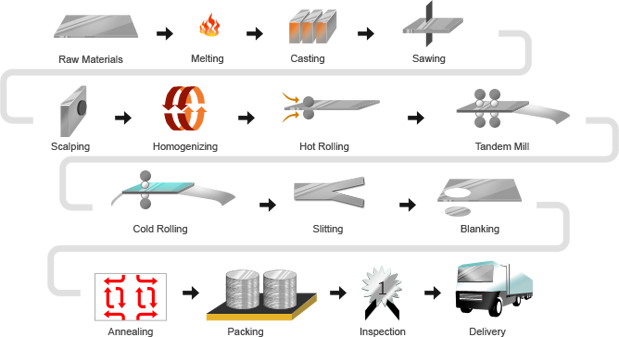

Ingot/Master Alloys --- Melting Furnace – Holding Furnace --- D.C. Caster --- Slab ---- Scalper --- Hot Rolling Mill – Cold Rolling Mill – Punching – Annealing Furnace -- Final Inspection – Packing --- Delivery

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.A1 |

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.5 |

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.6 |

1070 | 0.25 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.7 |

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.1 | - | - | - | 0.05 | 99 | |

3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 | - | - | - | 0.15 | 96.95-96.75 |

≧20 | ≧140 | ≧170 | ≧200 | ≧250 | ≧300 | ≧400 | ≧500 | ≧600 | ≧700 | ≧800 |

20 | 140 | 170 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 |

25 | 141 | 172 | 203 | 252 | 305 | 405 | 505 | 610 | 705 | 810 |

93 | 142 | 173 | 205 | 254 | 310 | 410 | 510 | 615 | 710 | 838 |

100 | 143 | 175 | 210 | 255 | 312 | 420 | 515 | 619 | 720 | 890 |

105 | 144 | 176 | 211 | 258 | 315 | 425 | 520 | 630 | 730 | 902 |

109 | 145 | 177 | 212 | 260 | 320 | 430 | 525 | 635 | 740 | 945 |

110 | 147 | 178 | 215 | 267 | 325 | 435 | 530 | 645 | 760 | 960 |

112 | 149 | 180 | 216 | 268 | 330 | 440 | 540 | 650 | 770 | 1000 |

115 | 150 | 181 | 217 | 270 | 335 | 445 | 545 | 655 | 780 | 1150 |

118 | 153 | 182 | 218 | 272 | 340 | 450 | 550 | 665 | 1200 | |

120 | 154 | 183 | 220 | 274 | 345 | 455 | 560 | 670 | ||

121 | 155 | 184 | 221 | 275 | 350 | 460 | 565 | 680 | ||

122 | 157 | 185 | 222 | 277 | 355 | 465 | 570 | 690 | ||

123 | 158 | 188 | 225 | 278 | 360 | 470 | 575 | |||

124 | 160 | 190 | 226 | 280 | 364 | 475 | 580 | |||

127 | 161 | 192 | 230 | 282 | 368 | 480 | 585 | |||

128 | 162 | 193 | 233 | 285 | 370 | 485 | ||||

129 | 163 | 195 | 235 | 290 | 375 | 490 | ||||

130 | 164 | 198 | 237 | 292 | 380 | 495 | ||||

132 | 165 | 238 | 293 | 385 | ||||||

133 | 166 | 240 | 295 | 390 | ||||||

134 | 167 | 242 | 395 | |||||||

135 | 168 | 245 | ||||||||

136 | 169 | 249 | ||||||||

137 | ||||||||||

138 | ||||||||||

139 |

* Please enquire if you are interested in products outside the above ranges

| Blanked and Sheared Circle Products | |||

| Thickness(mm) | Diameter Range (D)(mm) | |||

| D <= 455 | 455 < D <=1000 | 1000 < D <=1200 | ||

| .4 - 6.0 | +/-.079 | +/-.099 | +/-.015 | |

| ||||

| Packaging Details: | Packing: export standard, covering with brown paper and plastic film then packed with wooden case/palletPacking: export standard, covering with brown paper and plastic film then packed with wooden case/pallet such 2-3 tonnes in 1 wooden pallet. Such 18-22 tonnes in 1x20' container. |

|---|---|

| Delivery Detail: | Within 30 days |

Deep drawing quality, less scrap.

● Stock pots ● Fry pans ● Tea kettles

● Pressure cookers ● Pizza pans ● Rice cookers

● Restaurant cookware ● Coffee urns ● Electric skillets

Its good surface is suitable for the lighting industry.

● Recessed lighting ● High bay industrial lighting

● Stress lighting ● Traffic light reflectors ● Sports lighting

| Series | Temper | Alloy | Character | Application |

| 1 series | HO H12 H14 H22 H24 | 1050 | 1. Aluminium content>99%, excellent formability. 2. High reflectivity. 3. Stable performance for surface anodization. | 1. Ordinary cookware: extrusion pot lid, aluminium pot. 2. Lamp accessories: lampshade, downlights, laminate lights and street lights. 3. Indication signs and building materials: traffic signs, curtain walls, ceilings. |

| 1060 | ||||

| 1070 | ||||

| 1100 | ||||

| 3 series | 3003 | 1. Excellent formability. 2. High elongation, can be used in deep drawing process. 3. High grain grade, smooth surface and high reflectivity. | 1. Advanced cookware: non-stick pan, pressure cooker. 2. Lamp accessories: lampshade, downlights, laminate lights and street lights. 3. Indication signs and building materials: traffic signs, curtain walls, ceilings. | |

| 3004 | ||||

| 3005 | ||||

| 3105 | ||||

| 5 series | 5052 | 1. Low material density and low weight of finished product. 2. High tensile strength and elongation, good fatigue strength. 3. Higher grain grade and good surface finish. | 1.Advanced cookware: non-stick pan, pressure cooker. 2. Pressure vessel: pressure cooker, etc. | |

| 5754 | ||||

| 5083 | ||||

| 8 series | 8011 | 1. Excellent anodizing effect. 2. Stable performance and high surface quality. | Advanced cookware: can make pearl anodized cookware |

| ● Stock Pots | ● Fry Pans |

| ● Tea Kettles | ● Pressure Cookers |

| ● Rice Cookers | ● Pizza Pans |

| ● Electric Skillets | ● Restaurant Cookware |

| ● Coffee Urns | ● Bakeware |

| ● Steam Irons | ● Woks |

| ● Stainless Cookware Bottom Plates | ● Bread Makers |