Aluminium plate Supplier

Aluminium plate Supplier

The production of the aluminium circle is carried out on a fully automatic aluminum circle cutting machine from raw material feeding to casting and cutting. Aluminium coil rolls are made into round aluminum plate pieces directly without almost any manual intervention. The advantage of this production process lies in avoidance of scratches on the surface and high precise in size. Aluminium circle sheets have the following advantages.

1. Round metal plate of aluminium has a medium hardness suitable for further processing. As known to all, aluminum is a a metal of medium strength that can be bent freely and punched continuously into end products like pots, pans and strainers. This alone shortens production period and reduces cost substantially.

2. Aluminium circle sheets have an excellent performance in water resistance as well. Common end products of round aluminum plate pieces have no chemicals on the surface. Therefore, they do not catch fire even at a temperature of 600 centigrade, not to mention producing toxic gases. This makes it an environmental material in fire-proofing occasions.

3. In addition, a round metal plate of aluminium boasts a better resistance to oxidizing and corrosion. Aluminium circle sheets with an anodizing film of the regular thicknesses are mainly applied indoors, where they last for a long term without color fading, film peeling or surface corrosion.

4. Anodized aluminium circle discs, even the soft aluminium circle 1050, has a good hardness on the surface which is of a natural metal gloss that adds to luxury level and additive value of a product.

5. Round aluminum plate pieces have a strong resistance to stains. Finger marks can be removed effortlessly with a piece of cloth.

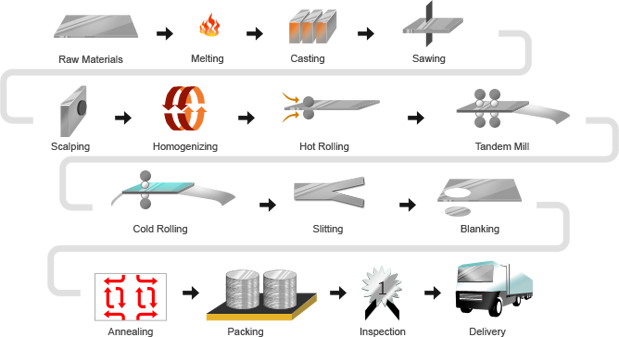

Ingot/Master Alloys --- Melting Furnace – Holding Furnace --- D.C. Caster --- Slab ---- Scalper --- Hot Rolling Mill – Cold Rolling Mill – Punching – Annealing Furnace -- Final Inspection – Packing --- Delivery

Aluminium round metal plate pieces are usually packaged in a cradle which meets the storage and transportation needs. The derrick frame is made of wood, and there are two wooden parts on both the upper and lower sides. Generally, the distance of the lower wooden part from the ground is set according to the requirements of the forklift operation. The arc shape corresponding to the radial direction of the roll is made on the upper side of the upper wooden side and then fixed by screws. The length of the screw is smaller than the surface of the upper wooden arc to avoid scratching the aluminium circle discs.

Method for manufacturing aluminum sheet circle for soft aluminum tube by aluminum rod

The invention relates to a production method for manufacturing an aluminum sheet circle for a soft aluminum tube by an aluminum rod, in particular to a method for extruding and punching the aluminum sheet circle. The method comprises the following steps of: selecting a raw material: the aluminum rod; carrying out axial cold deformation (wire drawing and drawing) on the aluminum rod; utilizing a cold heading machine or an automatic slitting punching machine to carry out directional extrusion on a cracked layer formed on a split blank, so as to shorten the area of the cracked layer to a corresponding range; carrying out secondary cold heading molding; carrying out complete annealing treatment on the aluminum sheet circle; carrying out surface treatment on a finished product; and checking and packaging. Compared with the prior art, a material returning phenomenon caused by punching through a traditional process is avoided and a directional extrusion and passivation technology is utilized, so that a turning procedure for overcoming the defects of pocking marks, pinholes and the like of the finished soft aluminum tube, which are caused by cutting off a cutting surface of the blank, is saved; the production yield is improved to be more than 99% from 60-70% of the traditional process, and the automatic production is wholly realized, so that the production efficiency is improved.